As with any mechanical system, maintenance on conveyor belts is to be expected. But not every breakdown is inevitable — a strong maintenance program can help you catch issues before they cause any significant damage to the conveyor system.

Updating your self-inspection process and backstock of emergency repairs and replacements won’t just improve your overall maintenance program. It is the key to increasing productivity and maintaining the reliability of belt performance. Follow these simple steps for improving your plant’s maintenance program.

First, understand your plant’s unique maintenance needs

Before you make major changes to your maintenance program and self-inspection process, it’s valuable to take time to define your plant’s unique needs. The maintenance plan for a glass processing plant (where belts undergo intense wear and tear) will be concerned with repairing belts until they run to failure. A bread plant’s self-inspection will be sure to include looking for fraying on belts to prevent replacement requests from sanitation inspectors. Understanding the needs of your conveyor system will not only help you make a better maintenance plan — it will make it easy for your conveyor belt technicians to understand exactly what you expect out of your belts.

General conveyor belt maintenance and self-inspection tips

The following tips can find a place in almost any conveyor belt self-inspection. They will help you catch problems earlier, preventing unnecessary downtime and improving overall system reliability.

Get a printable checklist version of these tips list by downloading our Guide to Conveyor Belt Maintenance.

- Review sanitation practices. Are sanitation crews cleaning with solvents appropriate for the belt material? Are they re-tensioning belts when they’re returned to the pulleys? Sanitation and belt life go hand-in-hand — make sure you’re doing it right.

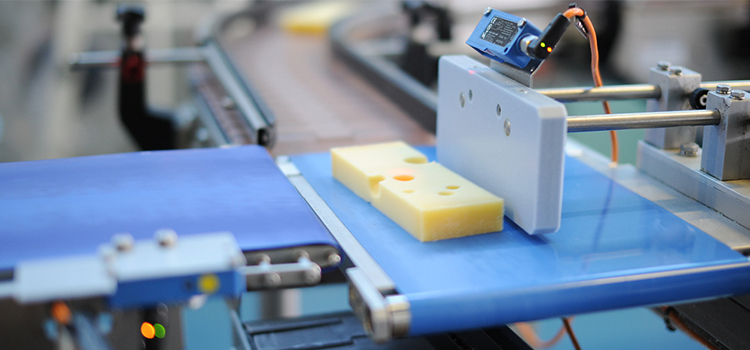

- Check for visual signs of damage. Are there strings or frays on conveyor belts or loose pieces on plastic modular belts? Are the belt covers starting to wear? These may be signs of impending catastrophic failure — make a note to repair or replace soon.

- Make sure belts are tracking correctly. Is the belt installed at the correct tension? Has the conveyor system been cleared of debris? Go through this checklist to eliminate causes of mis-tracking. Tracking is essential for reducing unnecessary wear on belts, maintaining belt life and ensuring a highly efficient plant.

- Backstock necessary spare parts and belts. What must-have parts (sprockets, drives, cleats, motors) do you need to have in-house? Be smart about what you backstock — if you have six machines running the same belt, stock two belts in your inventory, as you’re unlikely to have catastrophic failure on all six belts at once.

- Prep for emergency repairs on critical belts. Which application lines in your plant are critical? Stock emergency repairs, such as mechanical lacing or cold curing cement, for those belts so productivity isn’t lost.

- Track belt lifespan. Are belts lasting as long as they historically have lasted? This varies from plant to plant and line to line — some belts are replaced every shift in the meat industry, whereas belts are replaced every 5 to 10 years at distribution centers. A belt not lasting its typical lifespan is a red flag for a mechanical issue with the conveyor system that needs to be addressed.

Implementing any or all of these conveyor belt maintenance tips is valuable for maintenance managers looking to improve their maintenance program. By using this list, you can ensure your belts last their desired lifetime and your plant maintains high throughput and reliability.

Case study: Keen maintenance program leads to thousands in annual savings at food plant

At a plant processing raw potatoes and carrots, the maintenance manager noticed a belt with an unsatisfactory belt lifespan during his self-inspection. The hydrolift discharge conveyor conveying raw potatoes and carrots undergoes exposure to sand and dirt during processing and needs to withstand a high load. Unfortunately the belts, pins and sprockets weren’t holding up under these abrasive conditions. The on-site maintenance team was making repairs three to five times per month, and replacing entire sprockets multiple times a year — causing unnecessary downtime and ballooning maintenance costs.

Once the maintenance manager realized he needed to address the belt lifespan issue, he contacted his conveyor belting expert at MIR. After reviewing the belt and conveyor system, MIR made suggestions for a better-fit belt and modifications for the conveyor bed. MIR’s technicians removed the angle iron and shifted the snub roller down one inch on the conveyor bed. For the belting, MIR recommended an endless SuperDrive H Material belt that maintained the system’s positive tracking and food-grade sanitation level while minimizing maintenance concerns. SuperDrive H Material belts are easy to install and — most importantly — have a long operating life.

The potato and carrot processing plant spent around $15,000 annually on maintenance for the hydrolift discharge conveyor with the previous belting. The new SuperDrive belt ran without need for replacement for three years — a major improvement from multiple repairs and replacements every year. On maintenance spending alone (factoring in the cost for conversion), the plant saved $42,000 over three years. In addition, the plant’s business at the time came in at less than $5,000 annually. After the belt upgrade and modifications had been running for three years, the plant hit $105,000.

In this case study, updating the conveyor system to a better-fit belt led to significant savings and higher revenue. With an astute maintenance self-inspection plan, maintenance managers can play an active role in catching issues early on and begin finding efficiency-improving solutions.

Conveyor belt maintenance is a complex but essential part of any highly efficient plant. For more industry-approved advice from conveyor belting experts, download our Guide to Conveyor Belt Maintenance and Repair. We offer insights on conveyor belt repair, advice on troubleshooting tracking issues and a printable checklist for an improved maintenance program — freeing up your time to focus on improving plant productivity.

View Locations

View Locations 24/7 Service: 877-MIR-BELT (877-647-2358)

24/7 Service: 877-MIR-BELT (877-647-2358)