The MIR Belting Audit™ Request

Get a line-by-line itemization of potential ROI for each improvement — at no cost to your facility.

Get startedBottling & Canning

Speed and efficiency are vital for bottling and canning products across beverage sectors. Conveyor lines must fill PET, glass bottles or aluminum cans, transfer them without causing damage, apply labels to ensure product traceability — all while moving at a remarkable pace. To accomplish this, belts at Bottling & Canning facilities need to maintain gripping abilities throughout the belt life, resist damage, maintain product stability and meet FSMA standards. Using conveyor belting, plastic modular belting, high-grade PVC and precision-made vacuum belts, MIR provides solutions for application lines such as:

- PET inclines

- Case sealers

- Multi-lane conveyors

- Pasteurizer lines

- Accumulation tables

- Case packers

Recycling

The growth of recycling and reusing initiatives in companies and municipalities across the country has put increased pressure on Recycling facilities to operate at higher and higher efficiency. A wide variety of materials must be sorted, and conveyor systems need to be ready for whatever passes through. Conveyor belts must resist abrasion, cuts and splice failure from sharp objects and need chemical resistance to withstand the numerous chemicals and oils found in recyclable goods. And due to the combustible nature of the materials, fire resistant belts are essential as well. MIR provides conveyor belting solutions that meet these needs and facilitate larger improvements such as production streamlining. We supply belting for applications such as:

- Pre-sorting and sorting lines

- Eddy current lines

- Metal sorter lines

- Magnetic transfer lines

Card Personalization

The fabrication of extruded plastic into payment, identification and promotional cards is essential for today’s economy, and thus Card Personalization facilities require an extremely precise and efficient conveying process. During card issuance, PVC and polycarbonate-laminated cards must be accurately printed, embossed or engraved with identification details. The belts conveying these cards need to easily move and manipulate product to ensure the highest degree of accuracy.

In Card Personalization facilities, friction feeders and vacuum transport application lines require high-grip belting and accurate hole patterns, respectively, to efficiently convey the cards. And on inkjet application lines, the belts need high grip, smooth splicing and accurate tracking — any unforeseen movements and the integrity of the cards are at risk. To meet these conveying needs, MIR provides stable and elastic flat machine tapes, vacuum transport belts, high-grip belting and temperature resistant belting. Additionally, our team can engineer belts with cleat and profile additions, surface modifications or matched sets of precision endless belting to ensure an efficient personalization process. We provide these products for applications such as:

- Inkjet printing

- Embossing

- Lamination

- Friction feeder

- Affixing / attaching

- Cutting and punching

- Vacuum transport

- Packaging and mailing

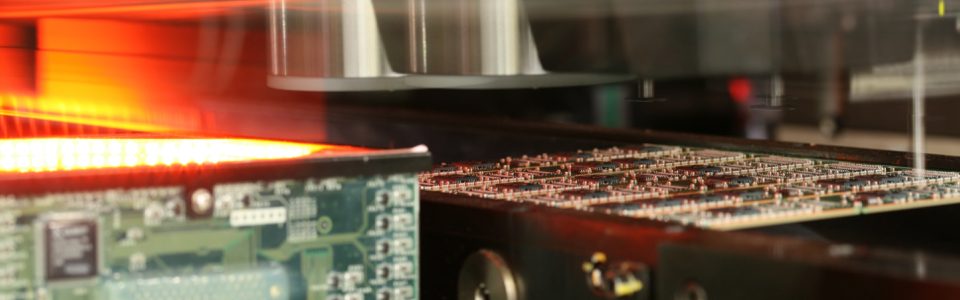

Circuit Board

Precise handling of the product is paramount at Circuit Board facilities, as these complex pieces of technology end up connecting computing systems that touch every industry and consumer. As these boards are screen printed, applied with surface mount technology (SMT) components and soldered, belts must convey them with the utmost exactitude, often moving them only along a single edge.

Circuit Board facilities require electrostatic dissipative (ESD) belts with smooth splices. This prevents static charges from damaging SMT components or mis-tracking from harming the boards or the application machinery. To meet these conveying needs, MIR provides precision or truly endless belts individually slit down to widths as narrow as 3mm and with tolerances as tight as +0/-0.5mm. Our unique slitting process produces a reliably tracking belt with smooth, straight edges. Additionally, our belts for Circuit Board facilities are either static dissipative or static conductive, the latter of which has an even lower surface resistivity than ESD belting and exceeds industry requirements. Finally, we use in-house meters to test materials and ensure they fall within the correct resistivity range. We provide belting for Circuit Board applications such as:

- Board handling conveyors

- Screen printing

- Placement systems

- Adhesive dispensers

- Soldering

- Wire cutting and stripping

Source durable, reliable conveyor belting solutions for Bottling & Canning facilities, Recycling facilities, Card Personalization facilities, Circuit Board facilities or other industrial processing plants. Click here to request a quote for conveyor belts engineered to your application’s exact needs.

View Locations

View Locations 24/7 Service: 877-MIR-BELT (877-647-2358)

24/7 Service: 877-MIR-BELT (877-647-2358)

Bottling & Canning

Bottling & Canning