Plastic & Steel Chains

Discover the power of innovation with our Plastic & Steel Chains, meticulously crafted to provide cutting-edge solutions for a multitude of applications across various industries. Whether you’re in baking, food packaging, hygiene, or any other sector, our chains redefine efficiency and reliability.

Why Chain Belts

When it comes to material handling, the choice between a conveyor chain belt and a standard conveyor belt can make a significant difference. Opting for a chain conveyor belt offers several distinct advantages. Unlike traditional conveyor belts, chain conveyor belts provide enhanced durability and reliability, making them ideal for heavy-duty applications. Their ability to handle a wide range of product shapes and sizes, as well as their adaptability to inclined or declined conveying, ensures versatility in various industries. Additionally, chain conveyor belts are easier to clean, ensuring superior hygiene standards, making them particularly well-suited for applications in food processing and pharmaceuticals. Choose a chain conveyor belt to experience enhanced efficiency, versatility, and longevity in your material handling operations.

Key Features and Advantages:

- Comprehensive Chain Variety: MIR Belting offers an extensive range of chains, dedicated to serving as drop-in replacements for chains from any brand. These chains seamlessly operate on existing sprockets and tracks, making retrofits and upgrades easy. Plus, our dedicated belting service is available 24/7 to support your needs.

- Established Industry Presence: Benefit from our strong market presence, where our slat top chains have become an industry standard, ensuring unwavering reliability and top-notch performance.

- Ready-to-Deliver Inventory: Experience the convenience of just-in-time deliveries with our consistently stocked inventory, proudly manufactured in the USA, and backed by our round-the-clock service.

- Competitive Pricing: We understand budgetary constraints and offer competitive pricing to meet your financial requirements without compromising on quality.

- Comprehensive Chain Portfolio: Our extensive chain portfolio encompasses plastic chain, low back pressure chain, snap-on chain, multiflex chains, crate chains, and steel chains, all meeting industry standards. We also offer cutting-edge materials to enhance your conveying efficiencies.

- Expert Engineering Support: Our dedicated engineering team stands ready to assist you in transitioning from any brand parts to MIR Belting’s chain solutions, ensuring a seamless and successful conversion process, available 24/7 to cater to your needs.

Product Categories:

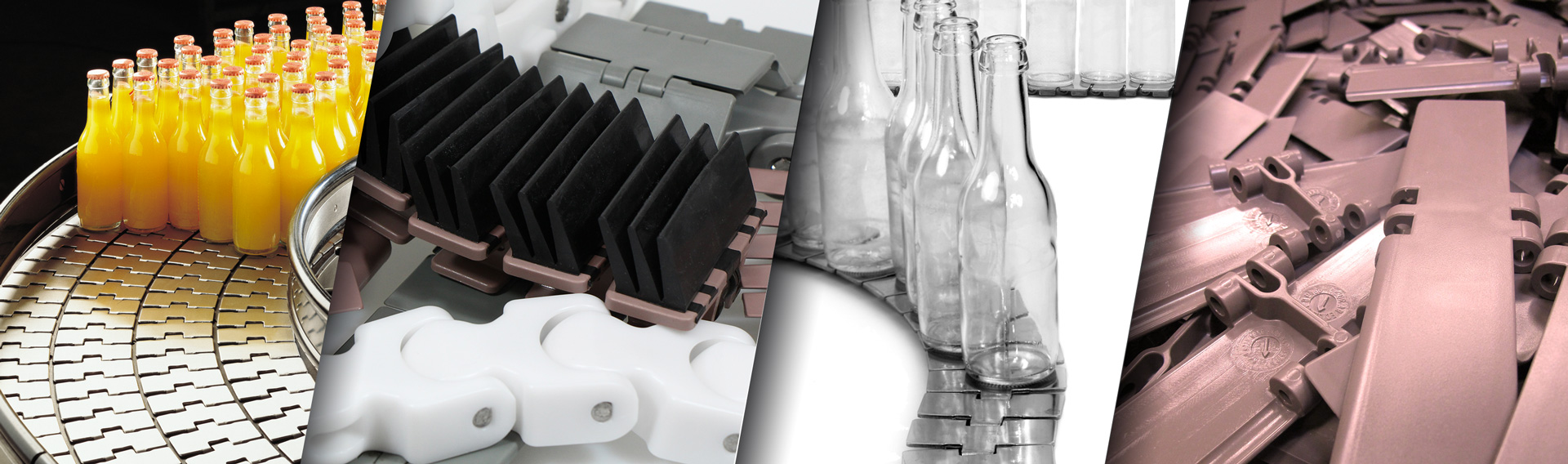

Slat Top Plastic Chain:

- Lightweight and Robust: Our plastic chains combine lightweight construction with exceptional strength, outperforming traditional steel chains. Experience reduced noise levels while maintaining superior durability.

- Premium Raw Materials: Crafted from high-quality raw materials, our plastic chains are engineered to deliver consistent and reliable performance throughout their lifecycle.

- Versatile Material Selection: Choose from a wide variety of materials tailored to meet diverse application requirements, ensuring a solution that perfectly matches your specific needs.

- Food and Packaging Industry Excellence: Tailored for the Food and Packaging Industry, our plastic chains provide reliable solutions for conveying various container types, meeting the highest industry standards for hygiene and efficiency.

- Application Versatility: Whether you require straight running or side-flexing capabilities, our plastic chains are available in different formats to accommodate curve hold-down systems, offering flexibility for various conveyor setups.

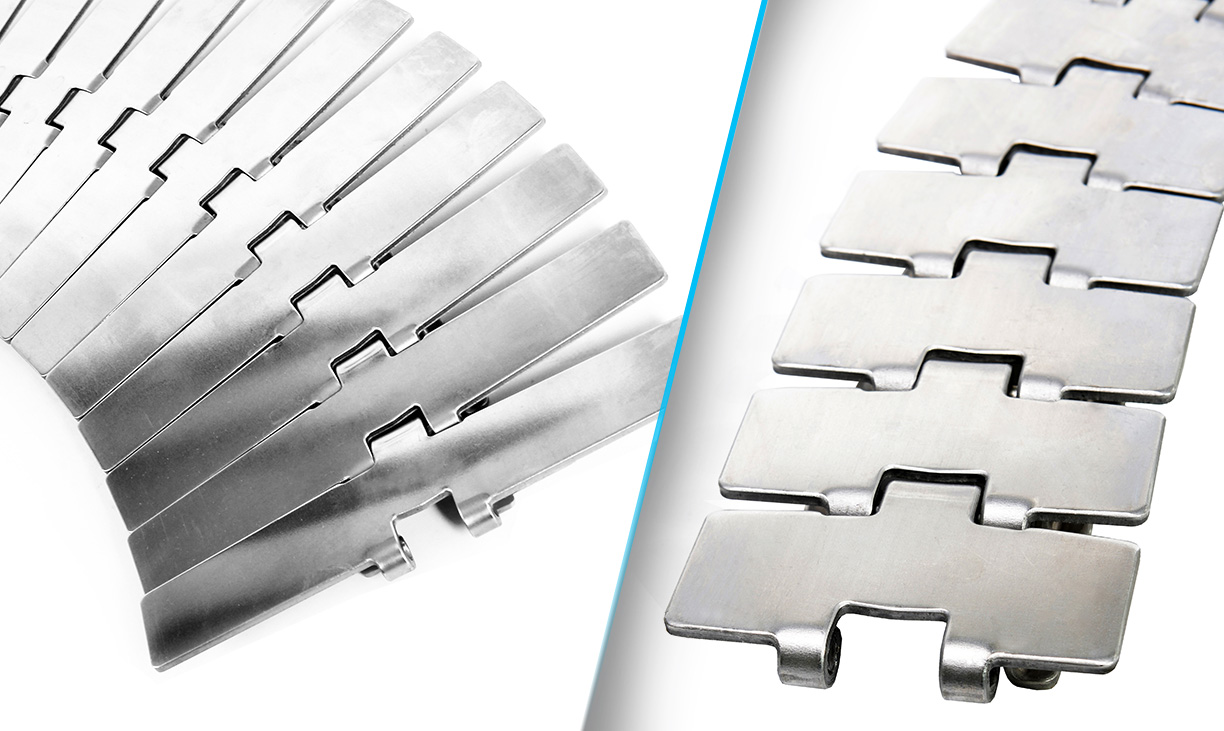

Slat Top Steel Chains:

- Glass-Resilient Performance: Designed for industries dealing with glass containers, our Slat Top Steel Chains are engineered to withstand the presence of broken glass without compromising chain function, ensuring uninterrupted operation.

- High Tensile Strength: Engineered for high-speed applications, our steel chains boast remarkable tensile strength, making them ideal for demanding conveyor systems that require precision and reliability.

- Dual Range Selection: Choose from our two exceptional ranges to meet your specific needs:

- Classic Range: This range features hardened carbon or ferritic/austenitic stainless steel chains, known for their durability and resistance to wear and tear.

- Plus+ Range: Elevate your conveyor system with our Plus+ Range, which includes work-hardened, chrome-nickel martensitic stainless steel chains. These chains feature a new surface finish, enhancing efficiency and reducing maintenance requirements, making them an excellent choice for high-performance applications.

Applications:

The suitability of plastic or steel chains for specific applications can depend on various factors, including the conveyor system’s requirements and the materials being handled. Here’s a general recommendation:

- Food and Packaging Industry: Both plastic and steel chains can be suitable. Plastic chains are often preferred for their hygiene and gentle product handling, while steel chains may be used in certain high-stress areas.

- Baking: Plastic chains are typically recommended due to their gentle handling of baked goods and resistance to moisture.

- Hygiene-Critical Environments: Plastic chains are preferred for their ease of cleaning and resistance to corrosion. Steel chains may be used in non-direct contact areas.

- General Manufacturing: Steel chains are often preferred for their durability and ability to handle heavy loads in manufacturing processes.

- Material Handling: Plastic chains are commonly used for material handling due to their lightweight and low-noise characteristics.

- Beverage Industry: Plastic chains are frequently chosen for their corrosion resistance and suitability for beverage handling. It’s important to note that the choice between plastic and steel chains may vary based on the specific requirements of your application and the conveyor system in use. Consulting with one of our conveyor systems expert or our technical support can help determine the most suitable chain for your specific needs.

Uncover possibilities in baking, food packaging, and hygiene applications, where our cutting-edge solutions stand out in terms of performance and durability. For personalized assistance with your specific application inquiries and to request a quote, contact your MIR Continuous Improvement Specialist. 877-MIR-BELT (877-647-2358)

View Locations

View Locations 24/7 Service: 877-MIR-BELT (877-647-2358)

24/7 Service: 877-MIR-BELT (877-647-2358)

Intro

Intro