Unlocking Bagel Production Excellence with MIR Belting Solutions: On The Hole, Our Bagel Belts Are Better

When it comes to crafting the perfect bagel, every detail matters, especially the conveyor belts that make bagel production efficient and consistent. At MIR Belting, where excellence in service is available 24/7, we understand that bagel making is both an art and a science. This is why we offer a range of specialized belting solutions designed to meet the unique needs of bagel forming machines. Our bagel belts are the result of years of experience and close collaboration with bagel machine manufacturers and bakeries, ensuring the highest level of performance and reliability.

Tailored to Your Needs

One size does not fit all in the world of bagel production. That’s why MIR Belting provides bagel belts that can be customized to your specific requirements. We emphasize the importance of precise dimensions, including the exact width and length or circumference. Our experts recommend measuring the length along the inside (pulley side) surface of the belt for the most accurate fit. Whether you need a new belt for mini-bagels or standard-size bagels, we have the solution you’re looking for.

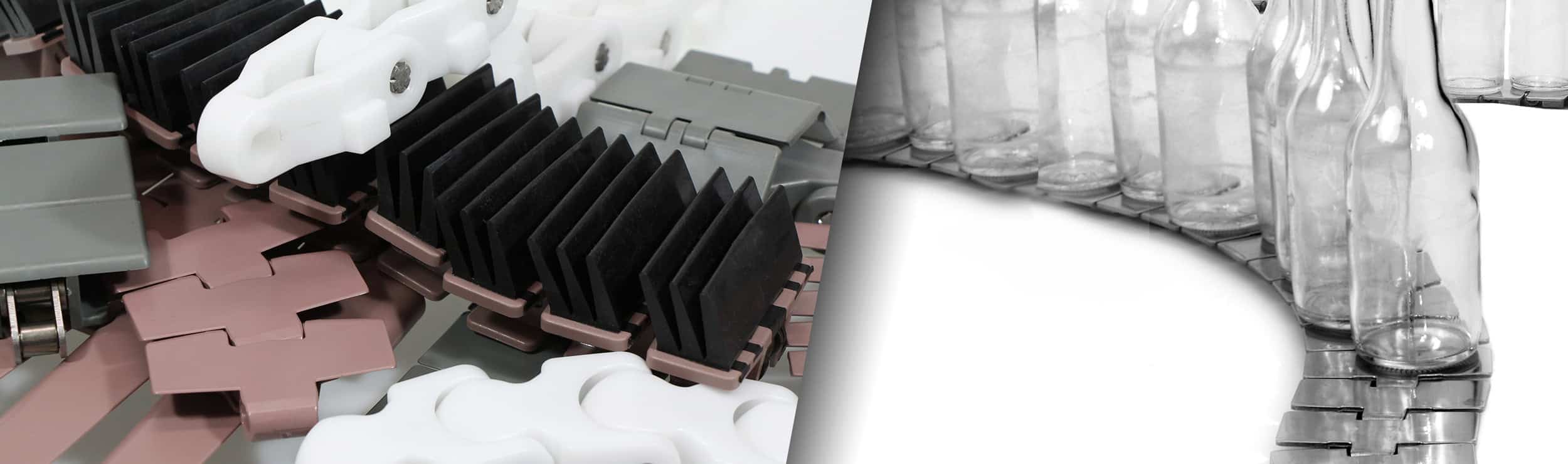

A Wide Range of Options

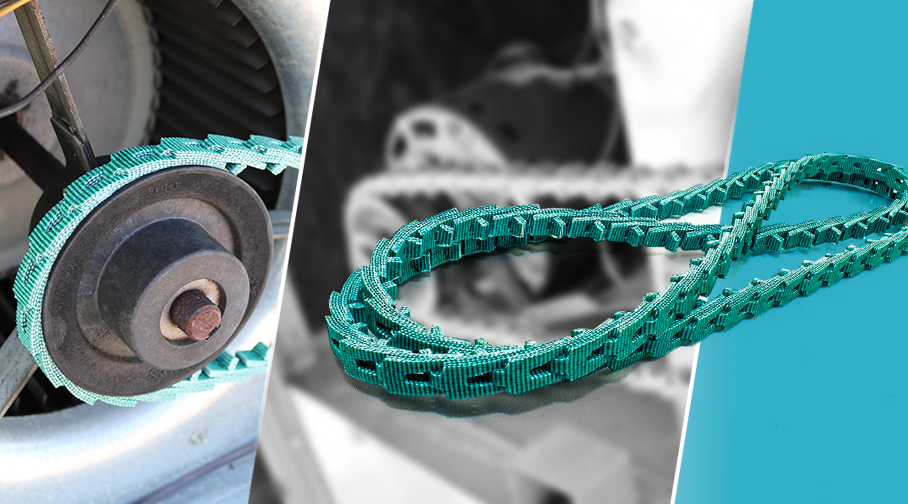

MIR Belting offers a variety of bagel belting materials to suit different applications. Some of our standout products include:

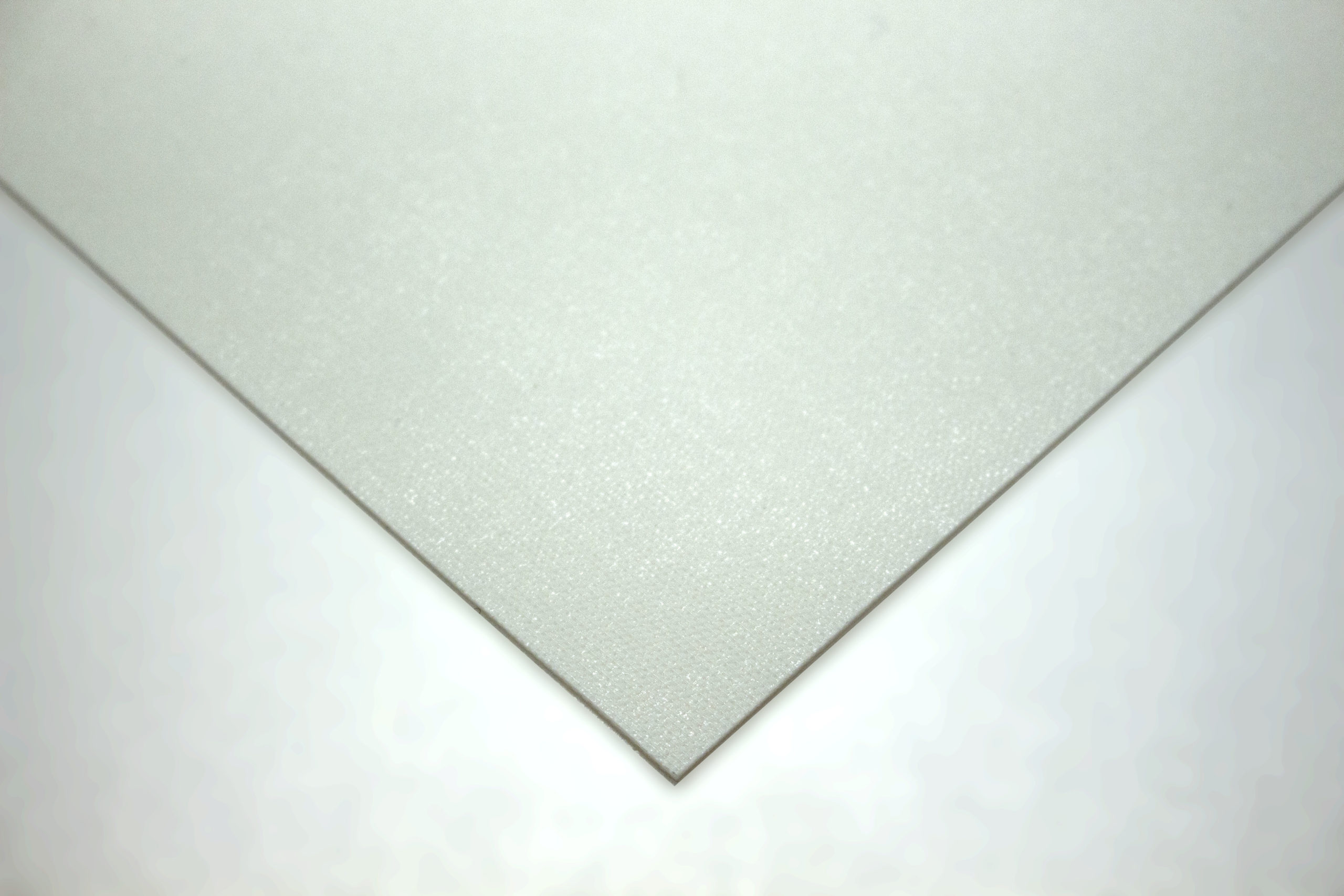

Fabric ESF 6/2 0+0 (PU) White FG (MIR-11112)

A 2-ply all-polyester belt with a textured top surface. Ideal for mini bagels. Features a robust bagel splice for lasting durability.

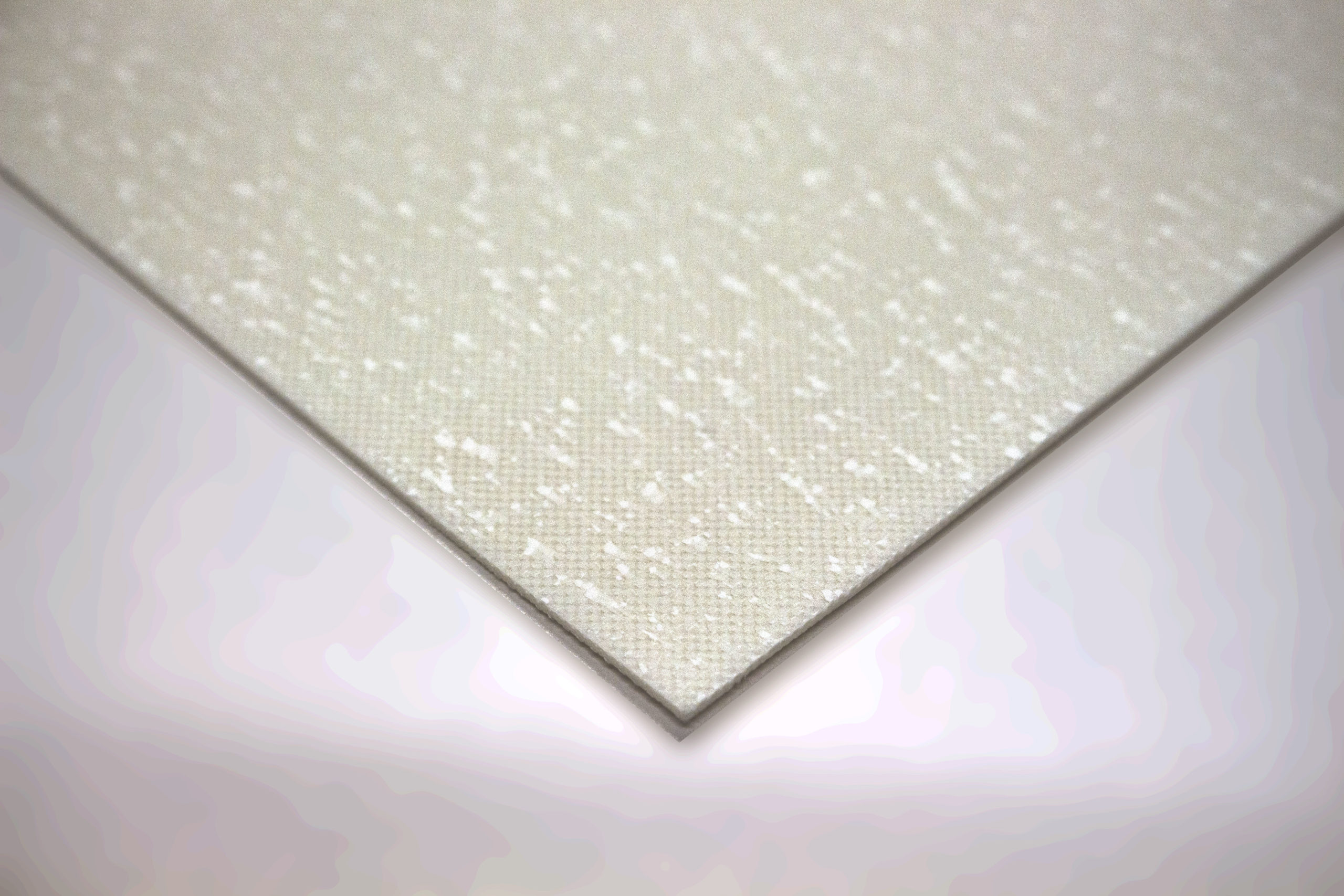

Fabric ESF 9/3 0+0 (PU) White FG (MIR-1999385)

A 3-ply, heavy-duty, all-polyester belt. Suitable for standard-size bagels. Offers maximum stability, width, and length. Boasts a strong bagel splice and low elongation.

Ropanyl EM 8/2 00+P7 White AS FG (MIR-1897625)

Equipped with a PU mini rough top cover for excellent wear resistance. Does not feature a top fabric, ensuring reliability in demanding environments.

More Than Just Bagel Belts

MIR Belting is your one-stop solution for belting needs in the baking industry. With a long-standing presence in the market and a deep understanding of customer requirements, we offer a wide range of belting products for production and packaging applications. Our dedicated sales engineers and representatives cover not only the United States and Canada but also numerous other countries. No matter where you are, we’ll connect you with the right people to provide you with the best belt for your specific job.

Service Beyond Expectations

At MIR Belting, we understand that downtime is costly. That’s why we offer 24/7 service and support to ensure your operation runs smoothly around the clock. Our commitment to excellence extends beyond our products to the service we provide, helping you maintain the highest levels of productivity and efficiency.

In celebration of National Bagel Day, trust MIR Belting to deliver the belting solutions you need to elevate your bagel production to new heights. With our expertise and dedication to customer satisfaction, you can count on us to be your partner in bagel success.

View Locations

View Locations 24/7 Service: 877-MIR-BELT (877-647-2358)

24/7 Service: 877-MIR-BELT (877-647-2358)