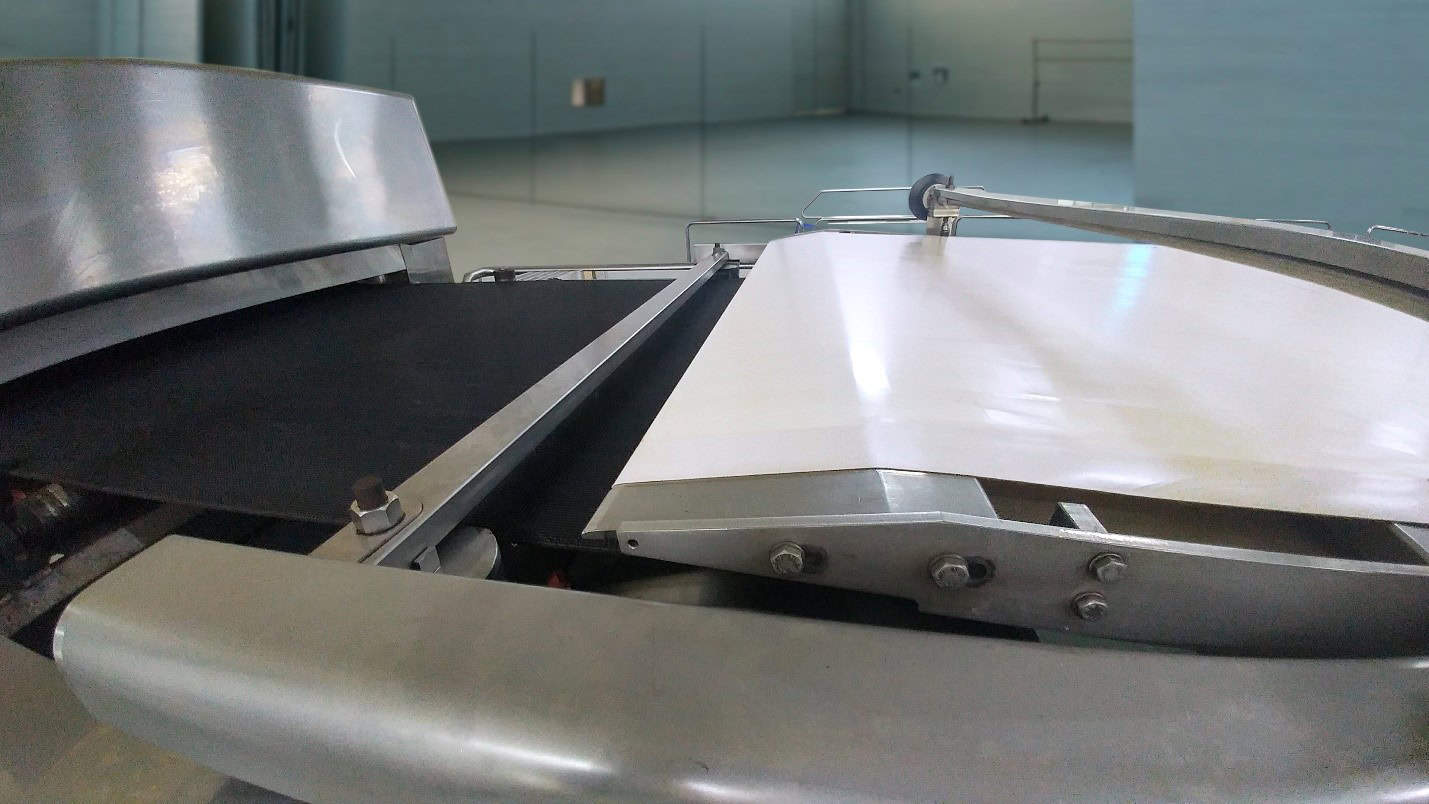

At MIR Belting, we are committed to providing innovative solutions for your packaging needs. We’re excited to announce that the newly launched Vertical Form-Fill-Seal (VFFS) belts from Megadyne are now available for you through MIR. This launch reaffirms our commitment to staying at the forefront of innovation and continually bringing new, cutting-edge products to our valued customers.

Who is Megadyne?

Megadyne is a global leader in the design, manufacture, and distribution of power transmission belts, known for their cutting-edge technology and exceptional quality. Their VFFS belts are engineered to provide superior performance, making them a trusted choice for various packaging applications.

Why Choose VFFS Belts?

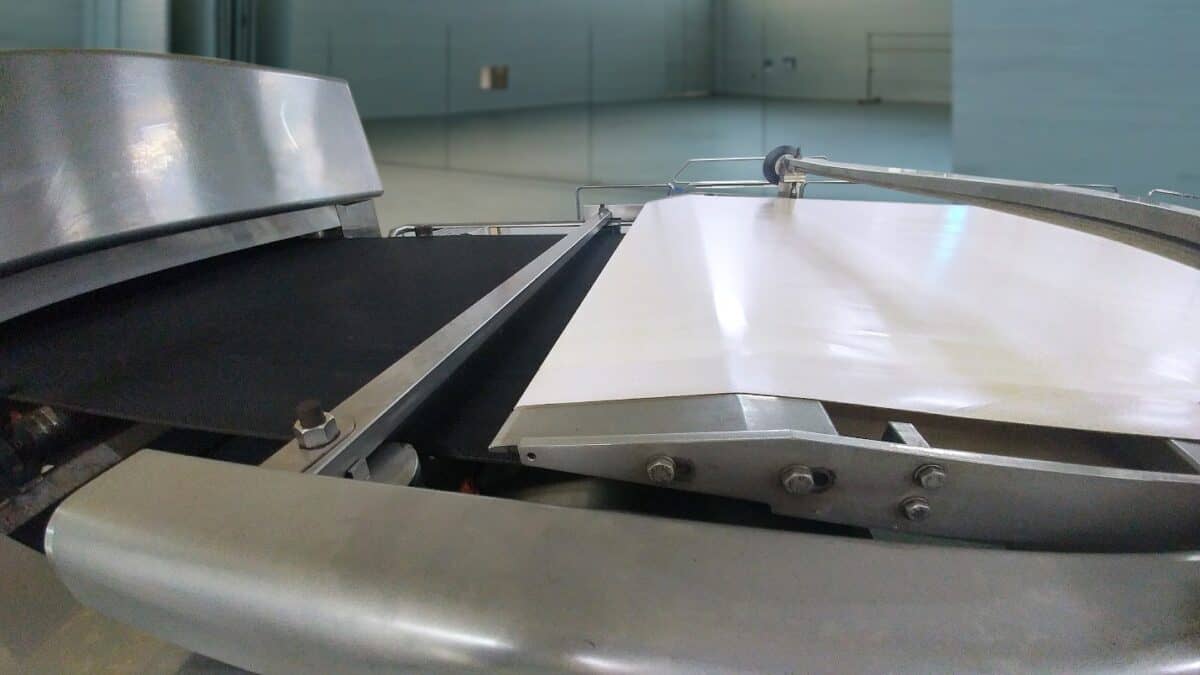

Superior Performance

Megadyne’s VFFS belts are engineered for reliability and durability, ensuring smooth and consistent performance even in high-speed packaging environments.

Reduced Downtime

The advanced design of these belts minimizes maintenance needs and reduces the risk of operational interruptions, keeping your production lines running smoothly.

What are the Key Features?

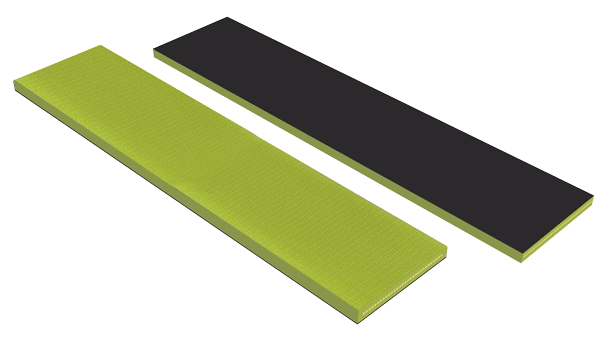

- High Abrasion Resistance: The belts are designed to withstand wear and tear, extending their lifespan and reducing the frequency of replacements. This results in cost savings and less downtime for maintenance.

- Optimal Grip: The unique surface texture of the belts provides an excellent grip on various packaging materials, ensuring precise and reliable handling of products. This leads to fewer errors and higher quality packaging.

- Customization Options: Megadyne offers tailored solutions to meet your specific needs, allowing you to get the perfect belt for your unique applications. This customization ensures optimal performance and efficiency in your packaging process.

Applications

VFFS belts are perfect for a variety of packaging tasks, including:

- Bagging dry goods such as grains, nuts, and powders

- Packaging liquid products like sauces and beverages

- Sealing frozen foods and ready-to-eat meals

Experience the MIR Difference

At MIR Belting, we pride ourselves on delivering top-quality products backed by exceptional service. By choosing the VFFS belts from us, you benefit from:

- Complimentary Belt Audits: Our experts will assess your current set-up and recommend the best belt solutions to optimize your operations.

- 24/7 Customer Support: Our dedicated team is always on hand to provide assistance whenever you need it.

- Industry Expertise: With years of experience in the belting industry, we offer unparalleled knowledge and guidance to help you achieve your packaging goals.

- Quick Deliveries: Quick shipping on many OEM replacement belts ensures minimal downtime and keeps your operations running smoothly.

Applications

Upgrade your packaging processes today with MIR Belting’s Vertical Form-Fill-Seal belts. Contact us at [877 MIR-BELT] (877-647-2358) or visit our website to learn more about how we can support your business.

View Locations

View Locations 24/7 Service: 877-MIR-BELT (877-647-2358)

24/7 Service: 877-MIR-BELT (877-647-2358)