Boost Your Operations with Unmatched Durability and Efficiency

Introducing the uni Industrial Thick Belt (ITB) – a robust and reliable solution for heavy-duty conveyor applications. Engineered to tackle the toughest industrial environments, this modular belt offers exceptional performance with its seamless design, wear resistance, and easy compatibility with existing systems. The uni ITB also offers a hassle-free solution that seamlessly replaces compatible belts from other leading brands.

Why Choose uni ITB?

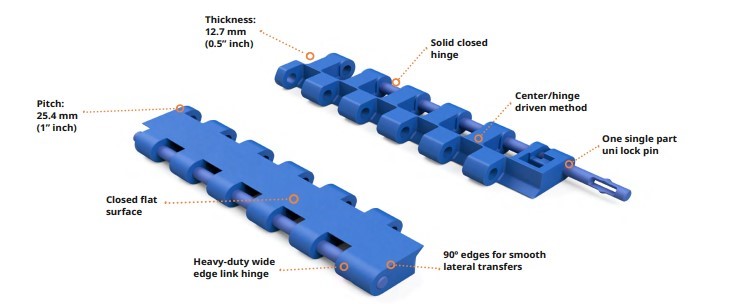

- Heavy-Duty Thickness: The 0.5-inch thickness ensures superior load capacity and enhanced wear resistance, ideal for abrasive environments.

- Easy Integration: Compatible with various products in the market, including Intralox 1400 series and existing sprockets, making it a drop-in solution without the need for conveyor modifications.

- Simplified Maintenance: Features the uni LockPin system for quick and easy installation, reducing downtime and labor costs.

- Enhanced Performance: Features the uni LockPin system for quick and easy installation, reducing downtime and labor costs.

- Interlaceability: The uni ITB’s design allows it to interlace seamlessly with various industry-standard belts, making it capable of replacing any brand on the market without requiring significant changes to your existing setup.

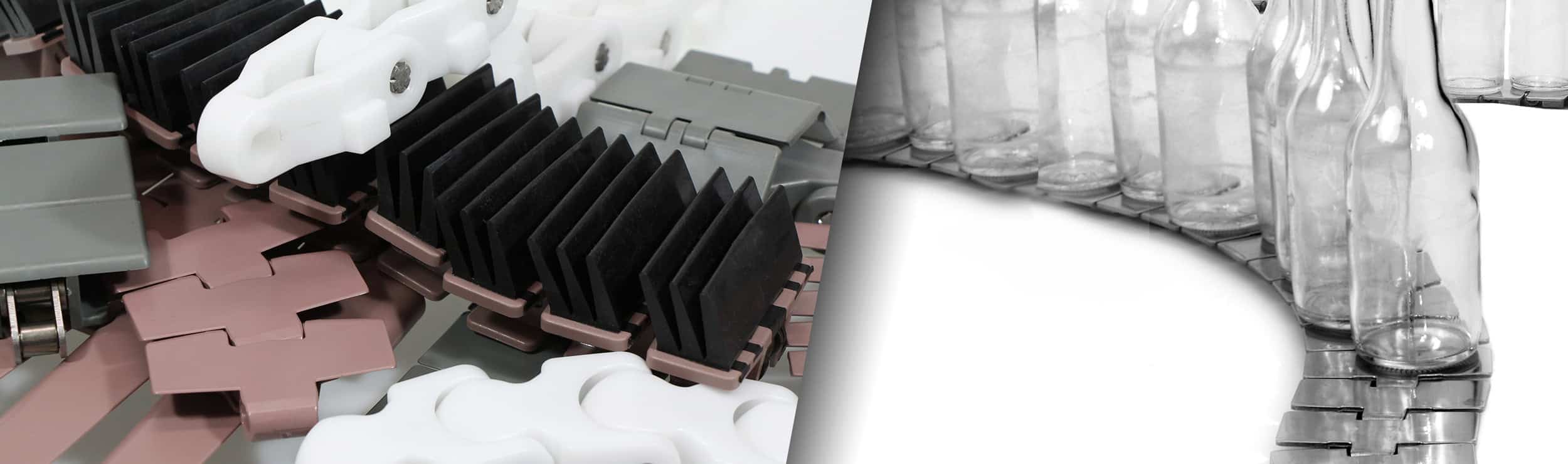

Applications:

Perfect for industries like Bakery, Beverage, Tire, and Corrugated packaging, the uni ITB is your go-to solution for reliable and efficient material handling.

Explore how the uni ITB can enhance your operations, now available at MIR Belting. Call 877-MIR-BELT or request a quote online.

View Locations

View Locations 24/7 Service: 877-MIR-BELT (877-647-2358)

24/7 Service: 877-MIR-BELT (877-647-2358)