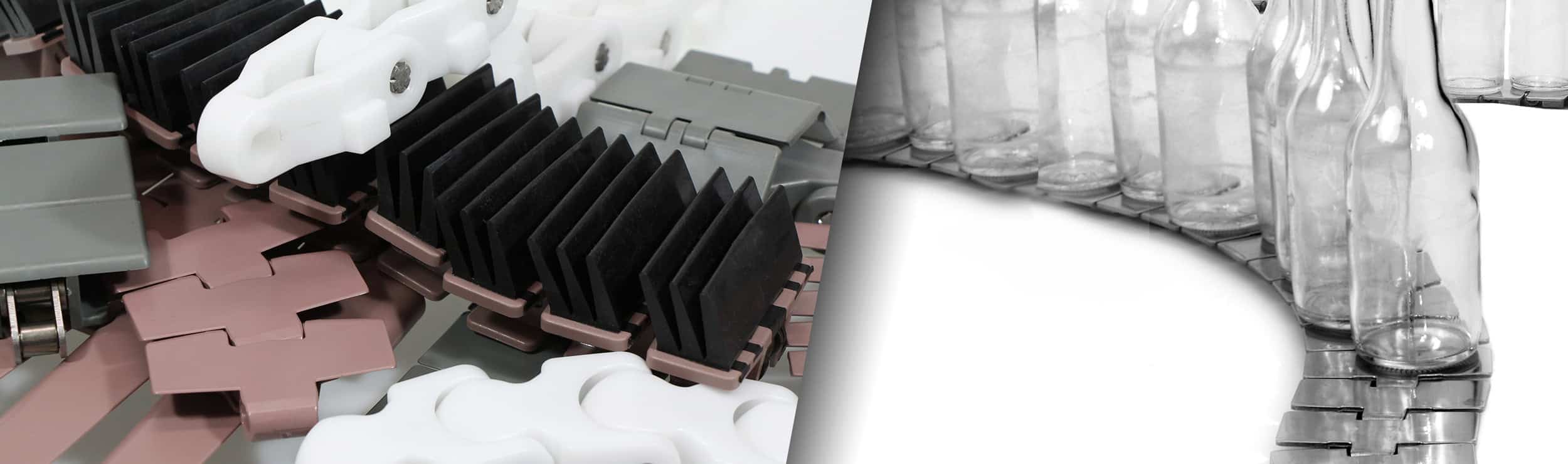

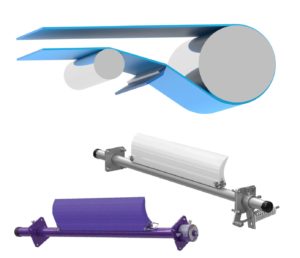

FRICTION FEEDER BELTS

Increase Belt Life. Improve Productivity.

Friction feeders help transfer mail pieces through to the next machine application for further personalization processing. Typical friction feeder belts experience gripping issues with glossy stock paper and are prone to frequent belt wear, leading to increased downtime.

Benefits:

- Longer Belt Life

- Improved Grip

- Increased Throughput

- Custom Compounds and Perforations

Click Here for full details.

Contact your MIR Continuous Improvement Specialist for specific application questions and to receive a quotation.

View Locations

View Locations 24/7 Service: 877-MIR-BELT (877-647-2358)

24/7 Service: 877-MIR-BELT (877-647-2358)