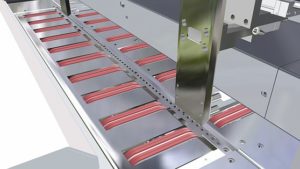

SLOW DOWN BELTS

Improve Delivery Times. Reduce Cost.

Slow Down Belts are used on Heidelberg Speedmaster presses to ensure proper stacking of sheets. Manufacturers frequently experience delays due to extended belt delivery time from OEMs.

Benefits of MIR Slow Down Belts:

- Ensure Proper Stacking

- OEM equivalent belts stocked in-house for immediate delivery

- Fabrication capabilities for custom sizes per your specifications

Click Here for full details.

View Locations

View Locations 24/7 Service: 877-MIR-BELT (877-647-2358)

24/7 Service: 877-MIR-BELT (877-647-2358)